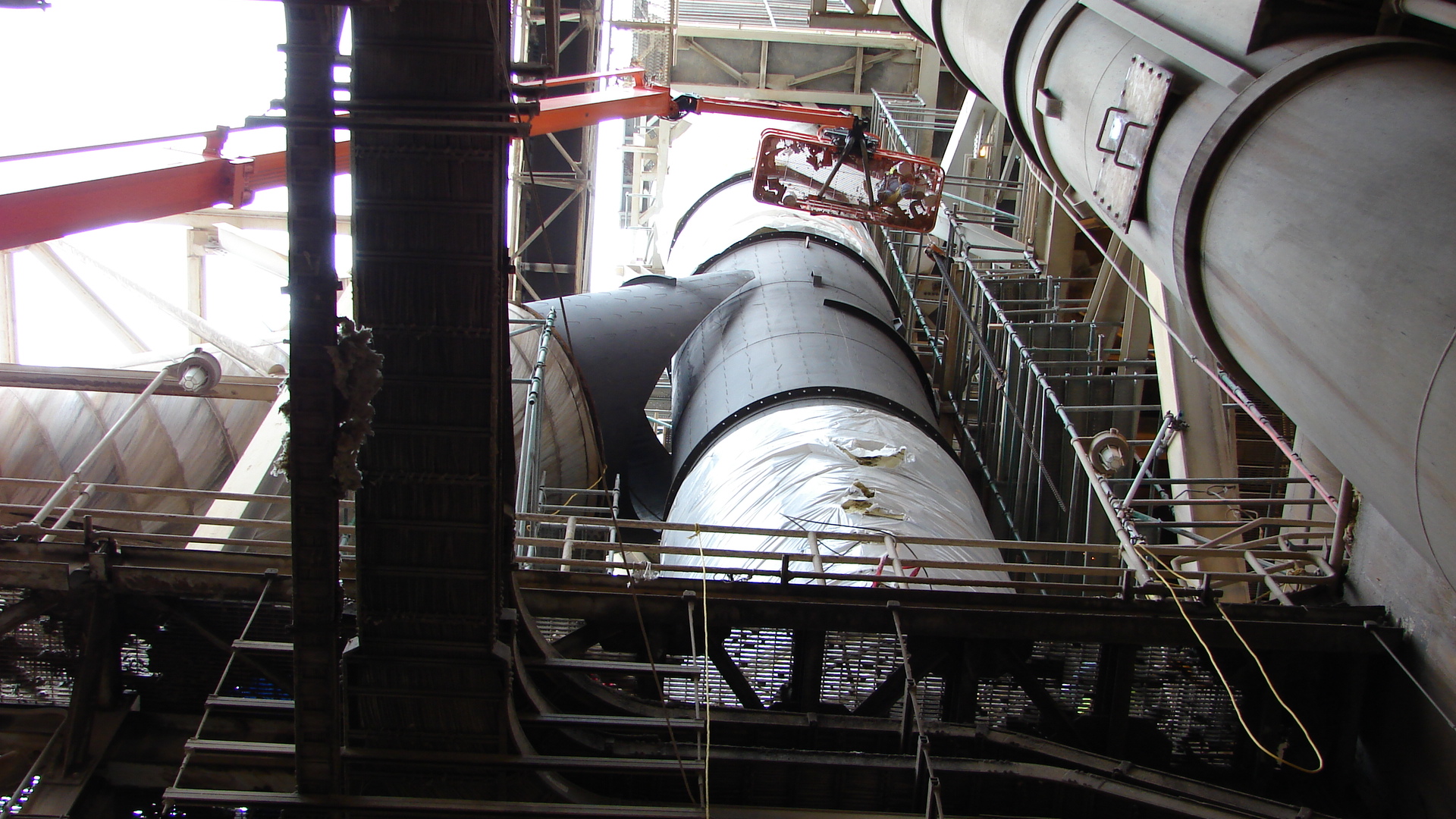

Downcomer Duct Overview

The downcomer duct is located between the top stage cyclone outlet of the preheating tower and the kiln Induced Draft (ID) Fan. Hot process gases from the combustion process are pulled down thru the duct by the ID Fan where they are cooled by water sprayers. The combustion gases that come out of the top stage cyclone have a certain dust loading or capturing element based on the cyclone efficiency thus leading to buildup in the duct work lining. Moreover, gases can be corrosive and slightly abrasive which causes wear and thinning of the duct. Also, suction pressure from being on the inlet side of the ID fan is an added element in deterioration. This is why a periodic thickness testing and inspection schedule of the duct will determine when replacement is necessary.

Job Overview

This current project is located in Calera, Alabama – which the client requested to remain anonymous. As a rule of thumb, completion of a project of this caliber is estimated to last around 20 days with crews working around the clock. Precise rigging is a must to safely remove all 10 sections. Moreover, mechanical rigging is instituted for extra support and removal assistance. Doing this allows for a safer working environment and precise removal of each section. After each section is unbolted and rigging established, a

Grove 550 ton Hydraulic Crane removes each piece so ground crews can disassemble and prep each section for scrap. Once the old duct work is completely removed and prep work completed, logistical arrangements are made for delivery of the new duct work. While on the ground insulation contractors complete their phase of the project by installing insulation and wrapping it in plastic. Doing this allows for a faster turn around and safer/easier way to complete the project. Once final installation begins lift plans and preparations are made to complete this phase of the project.

Recent Comments